Build Diary 03-December-05

Saturday, went to the airfield this morning. Just far to much water about to fly so

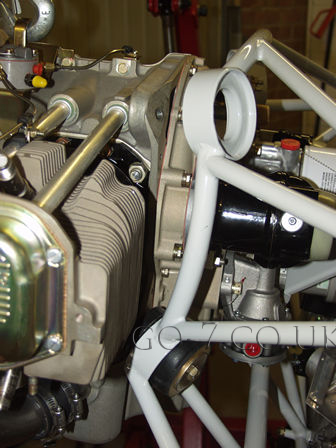

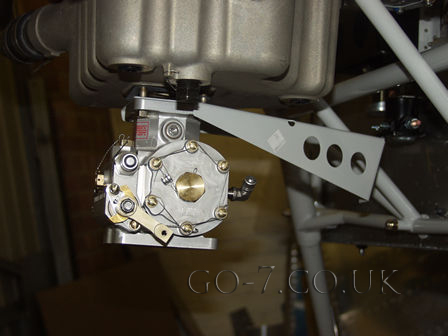

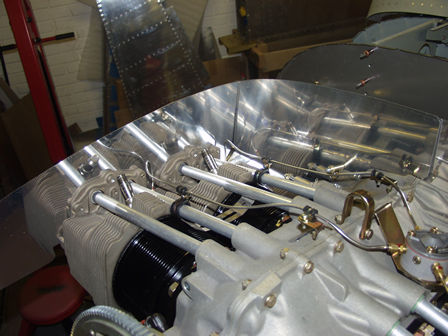

back to the workshop and fitted some parts to the rear of the engine then fitted the engine to the frame (the

fuse). I fitted it in under2 hrs on my own!!

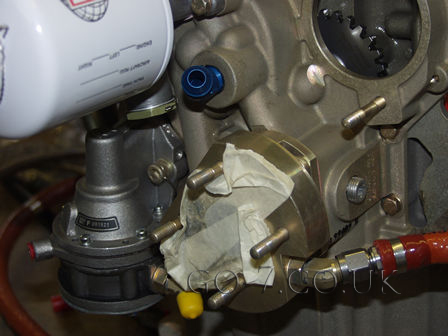

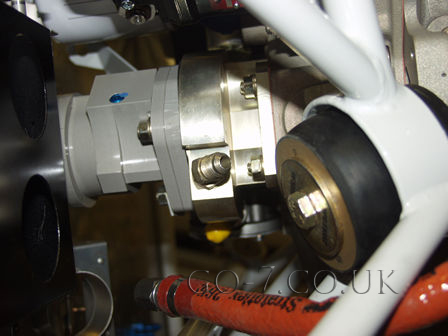

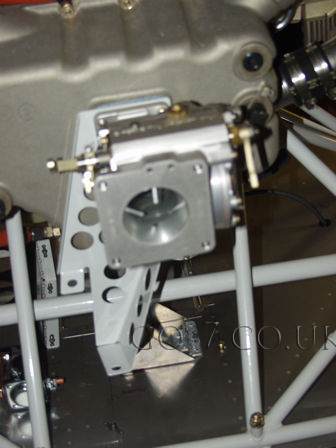

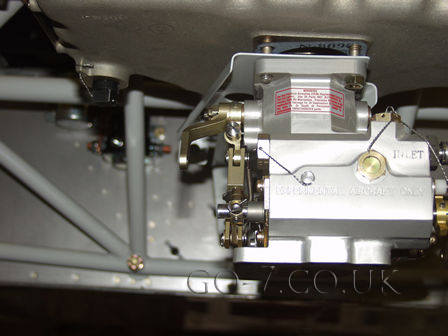

Started fitting parts to the engine, not going

straightforward as this is where differences between engine types need to be resolved. See picture

text......

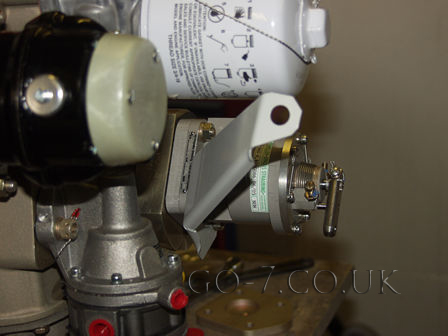

Another problem! The mixture lever will hit the airbox. This is a 3015002-1 Precision Fuel Injection servo. It should be a 3015012-1 which will reverse the mixture and allow a different arm to be fitted to operate from above instead.

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this site is the opinion of the author, not Vans Aircarft, PFA, CAA or FAA. Please check all information is correct before you act upon it.

Previous

page

Previous

page