Build Diary 29-May-06

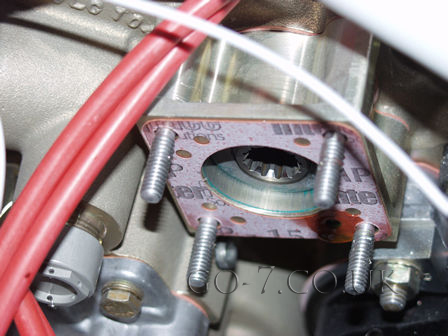

Worked on the cowl air intake today. The intake needs to be made level with the inner part of the cowl - just above the intake. This is to allow the air filter box to fit better. I have noticed some builders have not extented the intake, I almost didn't as I was able to make the air box fit. But decided today to do the extension as per plans.

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this site is the opinion of the author, not Vans Aircarft, PFA, CAA or FAA. Please check all information is correct before you act upon it.

Previous

page

Previous

page